What is Chicken Coop Wire

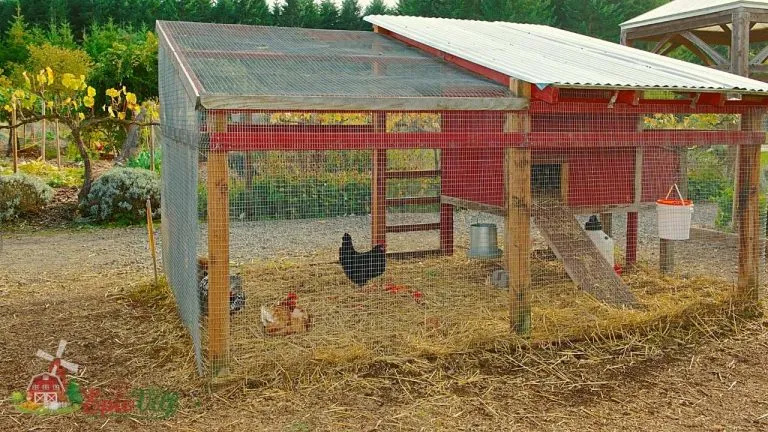

Chicken coop wire is an essential component of any secure and functional chicken coop. It serves as the primary barrier, safeguarding your flock from predators while also containing them within a designated space. The right type of wire provides ventilation, allows sunlight to reach the chickens, and helps to maintain a hygienic environment within the coop. Understanding the different types, materials, and installation methods is crucial for building a safe and effective chicken habitat. This guide will explore the critical aspects of selecting and using the appropriate wire for your chicken coop, ensuring the health and safety of your birds.

The Importance of Chicken Coop Wire

The importance of using the correct wire for a chicken coop cannot be overstated. It is the first line of defense against predators like foxes, raccoons, and hawks, which can easily access a coop through weak points. Beyond predator protection, wire also helps contain the chickens, preventing them from escaping and wandering into potentially dangerous situations. Properly installed wire also contributes to the coop’s structural integrity, providing support for the walls and roof. Ventilation is another key function, as the wire allows air to circulate, reducing the build-up of ammonia and moisture, which can lead to respiratory problems and other health issues for the chickens. Choosing the right type of wire is essential to ensuring the coop’s durability, longevity, and ultimately, the well-being of your flock.

Preventing Predation with Chicken Coop Wire

Predator protection is the primary function of chicken coop wire. Many predators are adept at exploiting weaknesses in coop construction. Foxes, for example, can dig under the coop, while raccoons are known for their ability to pry open doors and tear through flimsy materials. Using sturdy, properly installed wire is crucial to mitigating these risks. The wire should be strong enough to withstand determined attacks, and it should be installed in a way that leaves no gaps or weak points. Burying the wire around the perimeter of the coop is an effective method to prevent digging predators from gaining access. Additionally, securing all access points, such as doors and windows, with robust wire mesh will further enhance the coop’s security. Regularly inspecting the wire for damage or wear and tear is also essential to maintaining its effectiveness against predators.

Choosing the Right Wire for Your Coop

Selecting the right wire for your chicken coop involves careful consideration of several factors, including the material, gauge, and finish. The appropriate choice will depend on your specific needs, the predators you’re trying to deter, and the overall design of your coop. Quality wire will ensure the safety of your chickens while also lasting for many years. Considering all options will provide your chickens a safe and secure home. Researching the needs of your local environment is vital to making the proper decisions. Consider the local predator threats and the best options for your needs.

Wire Mesh Material

Wire mesh material choices play a critical role in both durability and security. Galvanized steel wire is a popular option because it’s strong, rust-resistant, and relatively affordable. Vinyl-coated wire offers an additional layer of protection against corrosion, but it can be susceptible to damage if the coating is compromised. Hardware cloth, made from heavier gauge wire, is an excellent choice for predator protection, especially against digging animals. When selecting a material, consider the local climate and the potential for exposure to the elements. Ultimately, the best material choice balances predator resistance, longevity, and budget considerations.

Wire Gauge

Wire gauge refers to the thickness of the wire. The gauge affects both the strength and the flexibility of the wire. A lower gauge number indicates a thicker, stronger wire. For example, 19-gauge wire is thinner than 16-gauge wire. For chicken coops, a gauge of 19 or 16 is usually recommended for the main structure, while heavier gauges, such as 14 or 12, may be used for areas that are more vulnerable to predator attacks. Selecting the right gauge is crucial to balancing security and ease of installation. Thicker wire provides better protection but can be more difficult to cut and shape during construction. Consider the size and type of the animals that will attempt to get to your chickens.

Wire Coating and Finish

The wire’s coating and finish have a significant impact on its longevity and resistance to corrosion. Galvanized wire is coated with a layer of zinc to protect it from rust. There are two main types of galvanization: hot-dipped and electro-galvanized. Hot-dipped galvanization provides a thicker, more durable coating. Vinyl-coated wire adds an extra layer of protection against the elements and can be particularly beneficial in areas with high humidity or exposure to corrosive substances. Choosing the right finish can significantly extend the life of your chicken coop wire and reduce the need for frequent maintenance. Be sure to consider the costs and benefits of each type of finish to select the best option for your needs.

Top 5 Chicken Coop Wire Facts

Fact 1 Wire Mesh Size Matters

The size of the wire mesh is a crucial factor in protecting your chickens. Small mesh sizes, such as 1/2 inch by 1/2 inch or 1/4 inch by 1/4 inch, are ideal for preventing predators from entering the coop. Smaller mesh sizes are also better at keeping small birds from escaping and preventing rodents from gaining access. Larger mesh sizes may be suitable for the coop’s roof or run, where the primary concern is ventilation. However, always prioritize security when choosing the mesh size for the walls and floor of the coop. Ensure that any gaps or openings are small enough to deter predators. The right mesh size balances security with ventilation and visibility.

Fact 2 Galvanized Wire for Longevity

Galvanized wire is a top choice for chicken coops due to its durability and longevity. The galvanization process involves coating the steel wire with a layer of zinc. This coating protects the wire from rust and corrosion, which are common problems in outdoor environments. Hot-dipped galvanized wire offers the best protection because the zinc coating is thicker and more resistant to damage. Using galvanized wire significantly extends the lifespan of the chicken coop. This reduces the need for frequent repairs and replacements. Investing in galvanized wire is a smart choice for anyone looking to build a long-lasting and secure chicken coop.

Fact 3 Burying Wire for Security

Burying wire around the perimeter of the chicken coop is a critical step in preventing predators from digging under the structure. Many predators, such as foxes and coyotes, are skilled diggers and can quickly undermine a coop if they are not deterred. Burying the wire at least 12 inches deep, and extending it outwards, creates a physical barrier that prevents animals from gaining access. You can use hardware cloth or a similar wire mesh for this purpose. The wire should be bent outwards at the bottom to create an L-shape, making it even more difficult for predators to dig beneath. This is a simple yet highly effective method for protecting your flock. This process is a vital step for providing security to your chickens.

Fact 4 Wire Installation Techniques

Proper wire installation techniques are essential for ensuring the effectiveness and longevity of your chicken coop. Start by stretching the wire tautly across the frame of the coop. Use staples or fencing staples to secure the wire to the wooden frame, ensuring that the staples are spaced closely enough to prevent any gaps. Overlap the wire at corners and seams, and secure them firmly. For the roof, consider using screws and washers to attach the wire. Inspect the installation carefully for any potential weak points or gaps, and address them immediately. Taking care during the installation process will greatly enhance the coop’s security. This will also help to ensure the safety of your chickens.

Fact 5 Regular Inspection and Maintenance

Regular inspection and maintenance are crucial for keeping your chicken coop wire in good condition and ensuring the continued safety of your flock. Inspect the wire regularly for signs of damage, such as rust, holes, or loose staples. Repair any damage promptly to prevent predators from entering. Pay particular attention to areas where the wire is exposed to the elements, such as corners and edges. Clean the wire periodically to remove debris and prevent the build-up of corrosive materials. Replacing the wire every few years is vital for safety and security. Regular inspection and maintenance will help to extend the life of your coop and keep your chickens safe. It is a good investment for the safety of your chickens.

Additional Tips for Chicken Coop Wire

Besides the key facts above, there are additional tips that can enhance the security and functionality of your chicken coop wire. Consider using a double layer of wire in vulnerable areas, such as the bottom of the coop walls. This extra layer provides added protection against predators. Use a wire mesh with a small gauge to prevent small predators from entering, such as rodents. Regularly remove any debris from the wire to prevent corrosion. Consider the local environment and any unique predator threats in your area. Customizing your coop to meet those threats will ensure the safety of your chickens. Always prioritize the safety of your chickens and the structural integrity of your coop.

Wire Placement and Security

Proper wire placement is critical for maximizing the security of your chicken coop. The wire should cover all potential entry points for predators, including the walls, floor, roof, and any openings. Ensure that the wire is securely attached to the coop frame. Consider burying the wire around the perimeter of the coop to prevent digging predators from gaining access. Overlap the wire at corners and seams to create a strong barrier. Pay close attention to the wire mesh size and gauge. Ensure it is appropriate for the local predators. Regularly inspect the wire for any signs of damage or weakness. Properly placed wire is the foundation of a secure and predator-proof chicken coop. Prioritizing security in wire placement will provide a safe environment for your chickens.

Frequently Asked Questions about Chicken Coop Wire

Here are some frequently asked questions regarding chicken coop wire.

What is the best wire mesh size for a chicken coop? The best mesh size is typically 1/2 inch by 1/2 inch or smaller to prevent predators from entering.

What gauge wire is best for chicken coops? A gauge of 19 or 16 is usually recommended for the main structure, while heavier gauges may be used in areas vulnerable to predators.

How often should I inspect my chicken coop wire? You should inspect your chicken coop wire at least once a month and after any severe weather events.

Should I bury the wire around my chicken coop? Yes, burying the wire around the perimeter is highly recommended to prevent predators from digging underneath the coop.

What type of wire is most durable for a chicken coop? Galvanized wire is a durable and popular choice due to its resistance to rust and corrosion. Regular maintenance and proper installation will increase the life of your chicken coop wire.